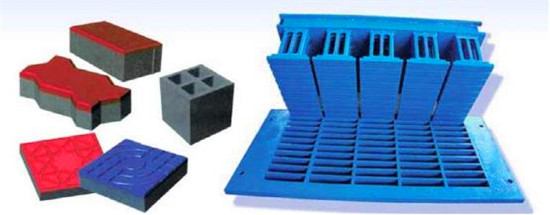

Zhongxing brick machine mould to build a cement brick mould without negative pressure.

In the manufacture of brick industry, especially cement brick, the mold USES more. In order to improve the production efficiency, the brick mould is usually set up with several separate brick cavity, which can be formed by making brick cavity. In order to reduce the weight of the bricks and reduce the cost of raw materials, the structure of the brick is not solid, adding the core part of the brick the mould making bricks internal structure change, get all kinds of demand of bricks. Core body usually by hanging rod welding on the brick mould, adjust or change more troublesome, also difficult to maintain after wear in use process, the process is very complex, when consumption is longer, the cost is also high. Hang lever and core body welding and core body on the cover plate welding, easily lead to structural deformation, need plastic processing, complex process, in addition, the process of open mould, the core body easy to produce negative pressure, affect the brick molding, high rejection rate, needs to be improved.

Zte brick mold mainly to solve the technical problem to reduce the effects of negative pressure is to provide a brick mold core body components, installation and maintenance convenience, improve core body to realize automatic mould when deflated, reducing the generation of waste.

In order to solve the technical problems, zte brick mold adopts a technical scheme is to reduce the effects of negative pressure to provide a brick mold core components, including: hang lever and a cylindrical core, a number of cylindrical core interval set below the hanging rod, cylinder cover fixed plate is set up, in the core barrel core in parallel with the very top cover plate fixed plate cover plate, plate fixed on the plate with a hole, hole has a downward extension of the guide sleeve is installed inside, inside the guide sleeve set down deflated rod, upper deflated rod set with a snap ring, snap ring set above the washer, deflated stem Settings are located on the washer at the top of the spring, and cover with a vent hole, deflated lever extends to the top of the vent hole. The cover plate is fixed in the cylindrical core. On the cover plate, there are several bolts connected with the cover plate. There are several screw holes on the cover plate, and the cover plate is set with the hole with the bolt. On the fixed plate of the cover plate, there is a fixed slot with hanger rod, and the bottom of the hanger rod is set with the limit block in the fixed slot of the hanging rod, and the hanger rod and the limit block are the integrated structure. The top inner concave of the two sides of the barrel core is set with the crossing groove of the hanger rod.

Zte brick mold beneficial effects: to reduce the effects of negative pressure brick mold, points out a kind of brick mould core components, the cover body fixed on the cylindrical fixed plate spot welding core, won't produce deformation, easy and hang lever to install and remove the cover plate and the maintenance is good, the brick production, hang lever driven cylindrical core, deflated at the bottom of the rod and plate contact stress increase, deflated bar at the top of the rise of vent hole sealing, avoid particles into the vent hole, open mold, hang lever to drive on the cylindrical core, deflated bar at the bottom of the lost drops rapidly under the action of forces in the spring, vent lose plugging and ventilation, to avoid the problem of negative pressure, improve the qualification rate of the brick.

Top brick machine mold, zte brick machine mold tell will continue to develop new type baking-free brick mold equipment, production of new wall materials and a variety of architectural energy saving products, bring more satisfaction to the domestic and foreign customers to use the mold.

Source: China machinery network.